Vilholi, Nashik, Maharashtra

- GST NO. : 27AAMFC4330M1Z8

| Business Type | Manufacturer, Supplier |

| Specifications | |

| Type | Single Screw Extruders |

| Certification | CE Certified |

| Click to view more | |

Preferred Buyer From

| Location | Worldwide |

Product Details

Application

Industrial

Weight

200-400kg

Color

Silver

Voltage

110V, 220V

Power

1-3kw, 3-6kw

Driven Type

Electric

Warranty

1year

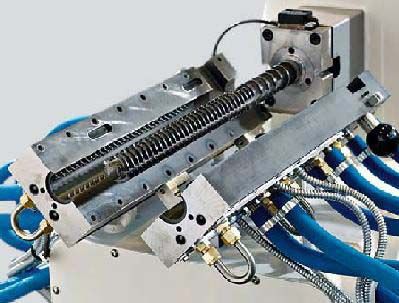

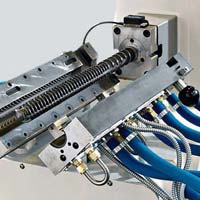

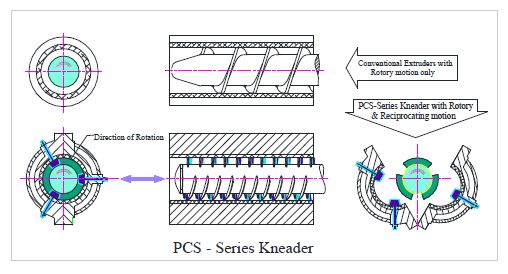

Relying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure.

Advantages

- No need of additional lab extruder for product development, shade / color matching, RM testing

- Easy & fast cleaning due to short length, easy & fast cooling due to water heating system

- Wide range of products can be produced on single screw extruder - like PU, PTFE, low curing, etc.

- Running cost is low as compared with Twin Screw - Low Power, Low heating cost

- Small batches can be easily possible

- Thorough cleaning is possible in small time span.

- Consistence product Quality possible due precise Temp Control, no problem of jamming, no problem of product deletion

- Low maintenance cost as compared with Twin Screw

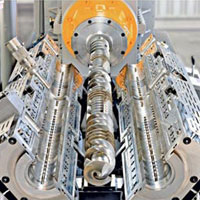

- Modular design of Screw Elements to felicitate the change in kneading / feeding lengths

- Thru Cooling Shaft - ensures the controlled process temp. / easy cleaning of screw & avoiding deletion in the barrel.

- process length is much less than the Twin Screw extruder, ensures less residence time for product.

- machine is easy to operate

- If power failure occurs - takes less time / less energy for restart

- Due close loop heating cooling system - load on chilling gets reduced drastically

Disadvantages

- Fine processing is limited to certain extent ( in case of rejection processing)

- requires extra care to be taken

- Spares cost is high ( but / kg cost is low as compared with twin)

- Thorough Cleaning is time consuming / you may need to keep spare set of Screw Shaft

Graph

Looking for "Single Screw Reciprocating Extruder (PCS 46)" ?

set

Explore More Products